How to Use a Pocket Hole Jig (Kreg Jig)

Learn all about how to use the pocket hole jig – otherwise known as a Kreg Jig! Use this tool to make your woodworking strong and tight with (almost) invisible screws. Perfect for DIY furniture and home improvement applications.

Have you ever heard of a pocket hole jig? One of the most popular brands is Kreg Jig, and it’s a super cool tool that you’re going to want to use if you are a woodworker – even if you are a novice woodworker.

You’ll use this tool to hide screws/screw heads and make strong, tight joints. This type of jig makes a woodworking project look professional. And you don’t need any experience to use one!

What is a Pocket Hole Jig?

Before I explain how to make a strong joint with this tool, I want to show you what it looks like. If you purchase a Kreg pocket hole jig system, you’re typically going to get a set pictured above.

There are other (more advanced) sets available for pocket hole joinery, but this is the one we have and use on our projects. It includes:

- Drill and drive bits

- Depth collar with a hex key

- Pocket hole screws in various sizes

- Clamp pad adapter

- Case

So why should you use one? Here’s what we love about our jig. If you need a project to be super-duper strong AND attractive, ditch the wood glue or a standard L-joint and use a pocket hold jig!

Benefits of a Pocket Hole Jig

- You can accomplish joins in a matter of minutes

- No alignment issues when joining two pieces of wood – it’s one hole

- No gluing required (though you can if you’d like to make the joint extra strong)

- No leaving your project clamped together for hours even if you glue

What Does the Joint Look Like?

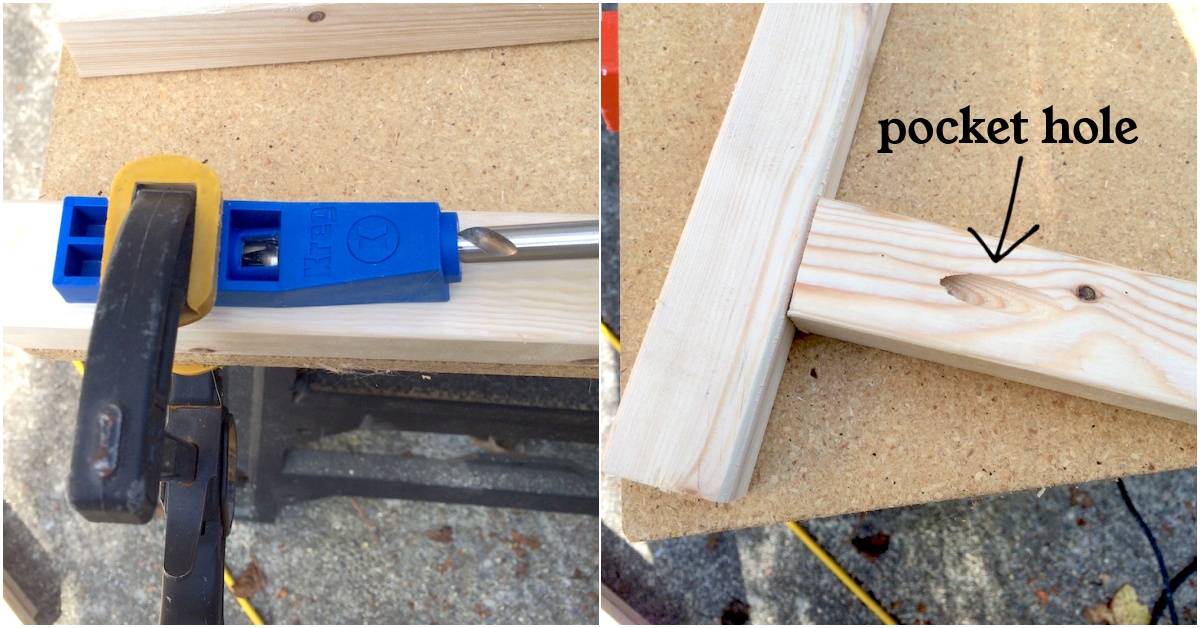

If you’re like me, you probably need it spelled out, so I’m going to start with a visual of a finished join we did using this tool. It’s probably going to look familiar to you:

The hole above is at a 15 degree angle, and the two pieces of wood were joined in just a few minutes. This join was created with one pocket hole, but we also use a two hole jig regularly.

To give you an overview of the process, you’ll create the pocket hole with your tool and a specialized drill bit that features a stepped pilot tip (included in your kit).

More on the Bits

The Kreg Jig Junior comes with two bits, a drill and a driver, shown above to the right of the tool itself.

The bit on the right drills a hole made so that both the tip AND the head of the screw will fit securely. This means the head will go down in the hole and be hidden.

The bit on the left is a square tipped driver that you can use in a standard drill, because Kreg Jig brand screws have a special head on them. Whether you use Kreg Jig screws is all about personal preference.

How to Use a Kreg Jig

I’m going to assume that (to start), you’re joining two pieces of wood at a right angle (90 degrees).

Make sure that your wood is cut with a miter or table saw set to 90 degrees so that you can have an absolutely smooth join. You don’t want any gaps in the wood.

Set the Depth on Your Jig

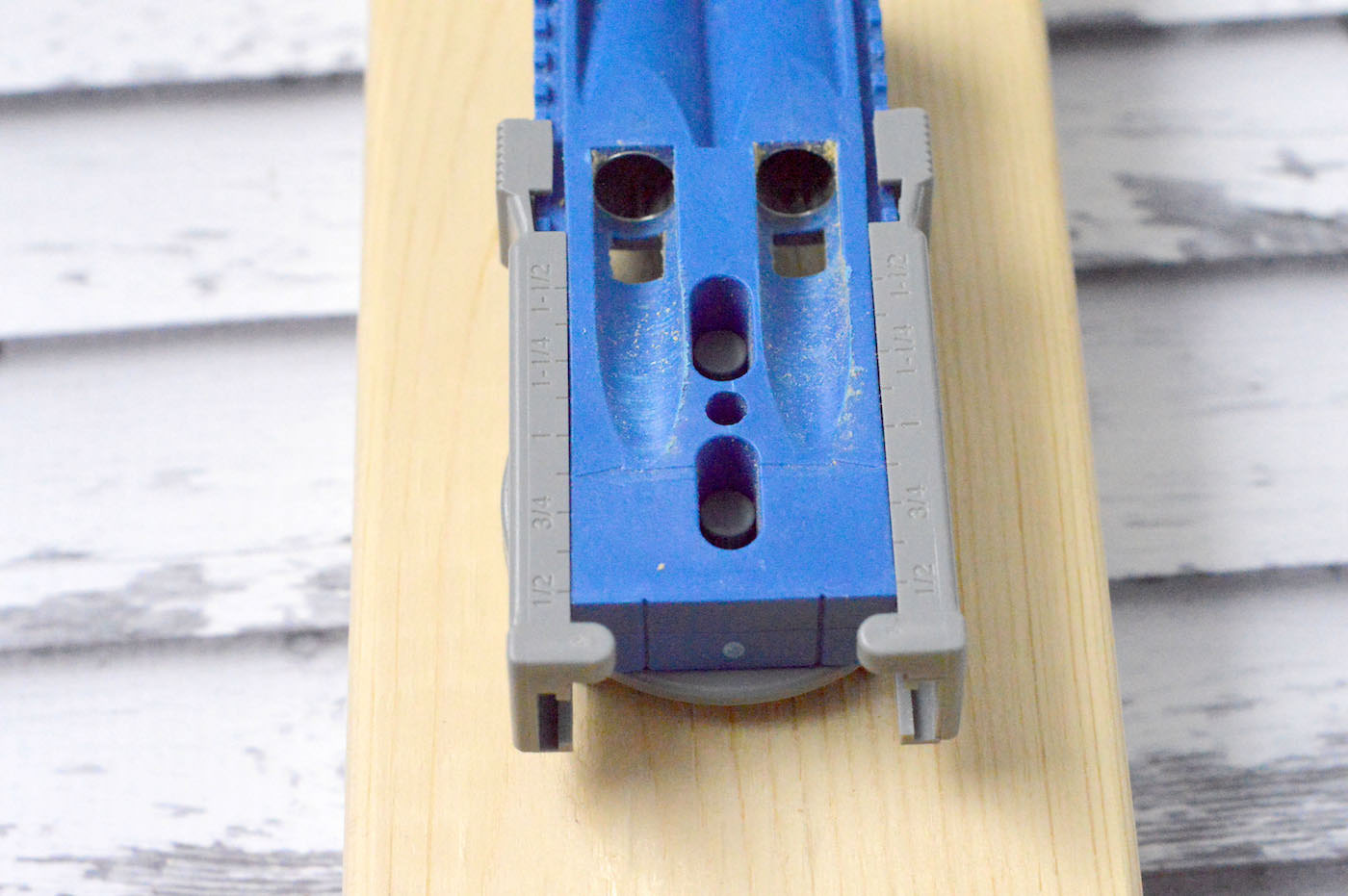

There is a numbered slide on the back of your jig which can be adjusted based on the thickness of your wood.

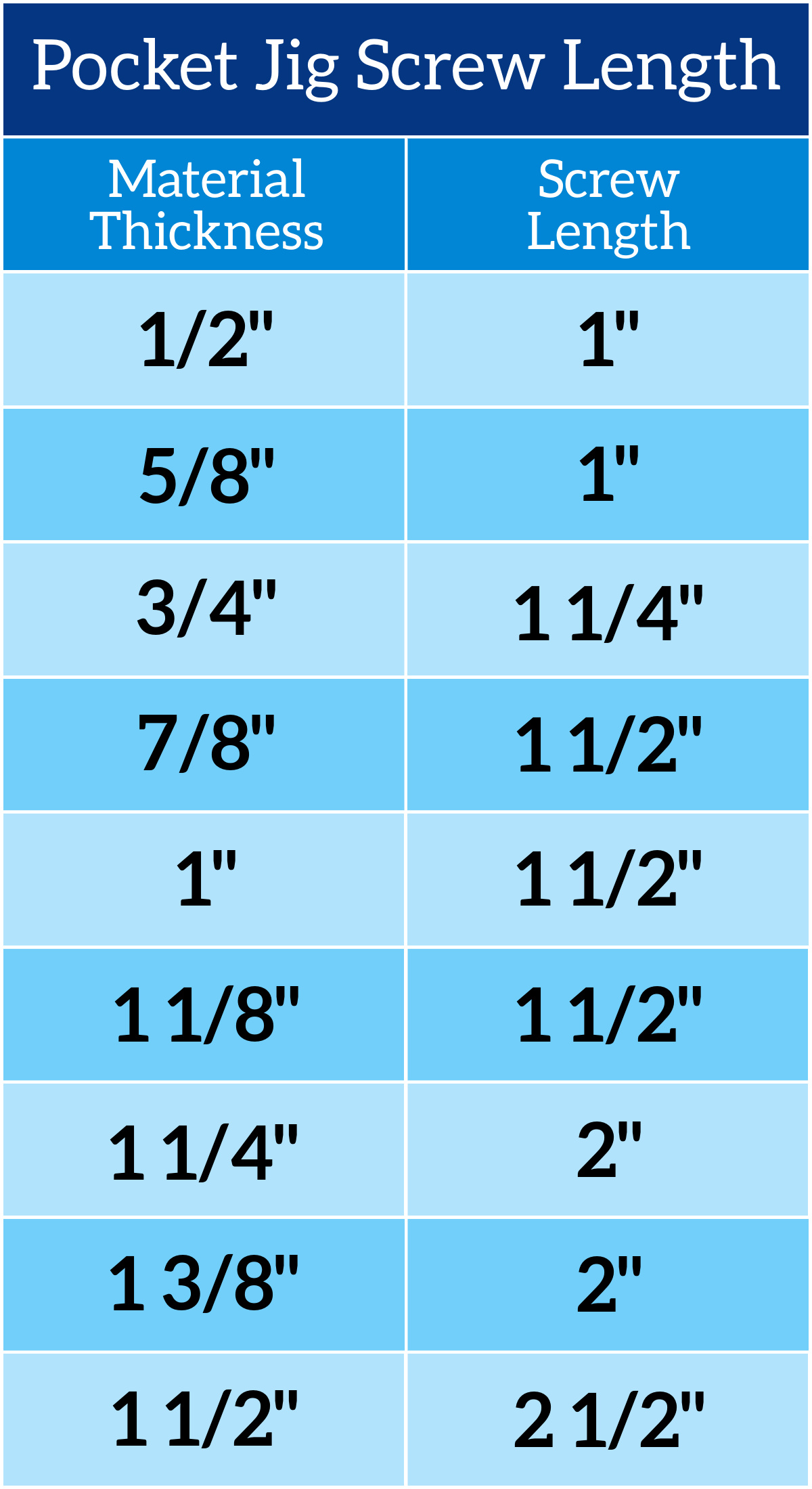

The Kreg Jig comes with a quick guide that provides the slider setting and screw length you’ll need based on how thick your wood is (I also have a chart at the bottom of this post if you scroll down).

If your wood is two different thicknesses, set the depth for the thinner board.

Clamp the Jig

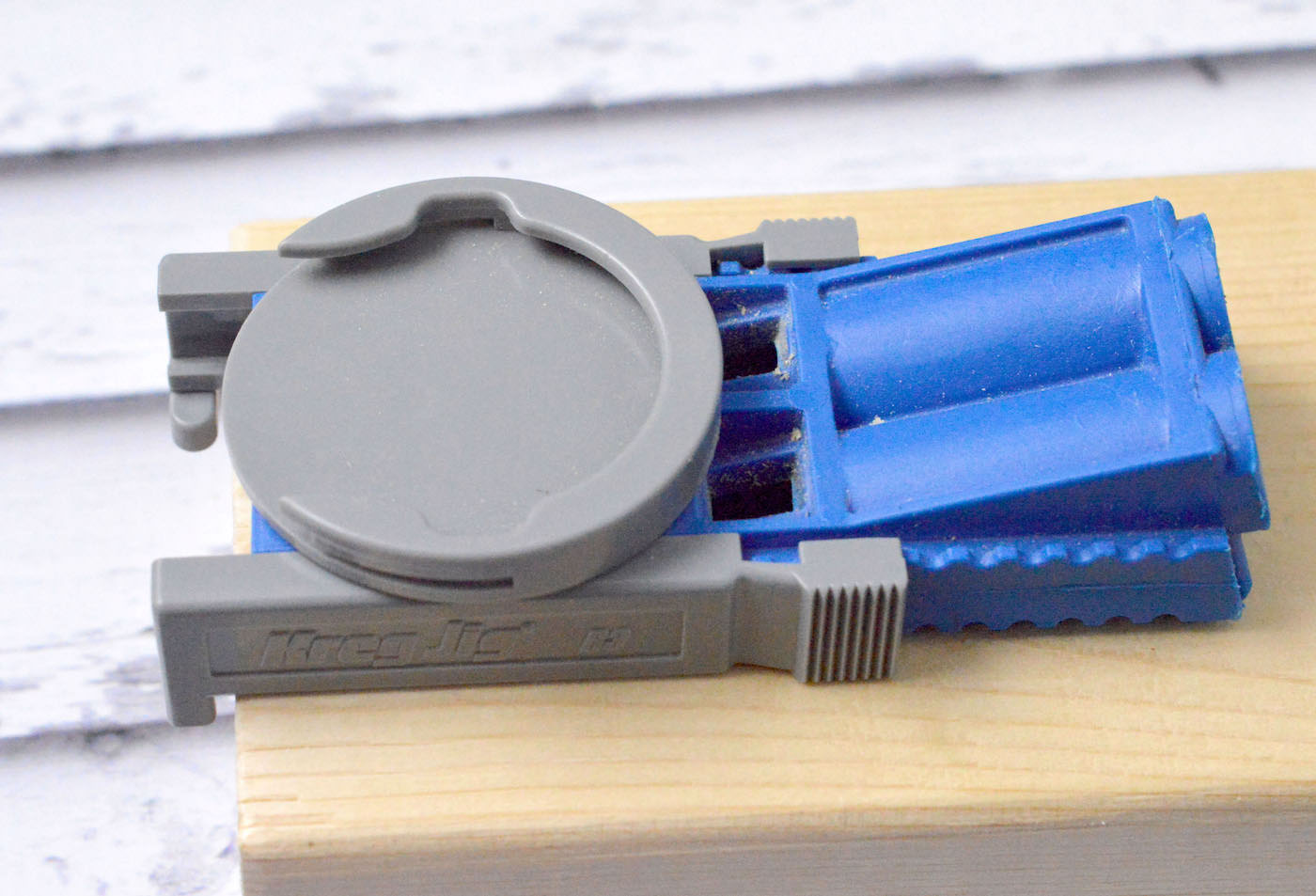

Flip the Kreg jig over after you’ve set it, and place it down where you want to join to be. The round, gray plastic piece above is where you will clamp the jig down.

I highly recommend a clamp as it frees up one of your hands. Also, clamps prevent “whoopsies.” You don’t want your pocket hole jig slipping out from under you as you’re drilling!

Insert the Drill Bit and Screw!

You’ll start with one piece of wood – the wood that you want the holes to go into. Make sure the correct drill bit is in your drill, and simply guide the bit through the holes in the Kreg Jig.

The jig will guide the bit and do all of the work; plus it has a stop collar when you reach the end. It’s easy to make straight holes without any issues missing the mark.

Basically, the only work you need to do is make sure your holes are lined up and then push the drill quickly and firmly through the hole. Repeat with the second hole if it’s a double pocket hole.

Then you’ll use two clamps to hold the two pieces of wood you want to attach together and drive the screws. They need to be self-tapping screws so that they drill into the pocket hole and second piece of wood easily.

Before you do this on a piece of furniture or other project you are building, I highly recommend trying it with two pieces of scrap wood. That way you can get a feel for the device and experience how easy it is to use.

Choose the Correct Screw Length

If a Kreg Jig guide is not available to you, use this chart to choose the correct screw length for your material thickness. The thickness of the board does matter.

Are you ready to get started with a pocket hole jig? Check out this video below that shows you the basic concept:

If you are interested in seeing our projects that use a Kreg Jig, here are a few of them!

- Farmhouse DIY Mirror Frame for $25

- DIY Pallet Hose Holder with Planter

- DIY Outdoor Table for a Charming Backyard

- DIY Coffee Table with Storage (Farmhouse Style)

One last thing! Don’t forget to visit our other tool guides: reciprocating saw, electric sander, router, and jig saw.

Just a little helpful advice, I apologize if it comes across as otherwise, you don’t have to use the Kreg brand screws BUT you’ll get better results if you use self drilling/tapping screws because the tips are sharper 🙂 Great post! A++

Thank you! That is great advice!

It’s shocking that Kreg made a special screw with a “special” head that no tool will work. No allen wrench, no star wrench, no phillips, no nothing. So then one would ask, “well then what tool do i need to buy if the 6 foot included one is too long, and google search after google search and no one mentions, “oh by the way, if you are working on a project that requires a smaller”tool” and the 6 foot long one we included for you is too long, then you will want to buy this smaller one. But nope, no mention, anywhere, nothing about what kind of tool it is, nothing on where to buy it, nothing. All that is mentioned is to use the extremely long one that is included and off you go. So shocking that such a cool jig is created by the same people that stick you with a screw that you have to use THEIR tool to use, but then don’t tell you where to get that tool, what it’s called or even acknowledge that “you might need other variations of this tool to tighten OUR screws, but we’re not going to mention that and we’ll let you scour our website, do dozens of google searches, watch countless Kelg videos and no mention. Not even one. Unbelievable. I feel like returning the screws and never looking back just for that alone.

@Mark, it’s not a special tip it’s Square drive. You can buy them from any hardware store

@Mark,

The screws are not new or special.

Read below

https://www.familyhandyman.com/article/diy-dictionary-what-is-a-robertson-screw/

@Mark, its a #2 square drive bit. I use this all the time and never have any issues with it.

@Mark, I just buy my furniture pre-made because of kreg using magic screws.

Is it possible to drill pocket holes in two flat pieces of wood that have already been glued together? No right angles involved, just two, glued together flat

boards that need extra holding power.

If this is doable, please enlighten me!

Thanks!

Question when you give the thickness of the wood are you going by the actual thickness or what the manufacturer does lets say its a 1×3

You want to go with actual thickness as opposed to “dimensional” sizing which is what the manufacturers use 😀